How to Order Custom Flanges?

A flange industry must focus on specific flanges like ASME, ANSI, AWWA, and industry-standard flanges that specialize in customer order flanges. With a wide range of systems, shops, and industries dependent upon high-performance flanges, custom pipe flanges are essential to get the job done correctly. Modified and custom flanges for specialty projects may offer the performance expectations, inspection requirements, same quality. They may also offer material, specific sizes, or fit for a unique application.

How does custom flange ordering work?

Job shops specialize in custom work that often requires large

quantities of raw material ready to be crafted in the shape, style, and size of

flange a customer requires. It includes modification on industry-standard

flanges or unique shapes like:

- Reduced flanges

- Flanges with spools

between custom layers

- Flanges with dual

bolt patterns

- Square pipe flanges

How to order a custom flange

The first step to order a custom flange is to gather as much

information as possible about the flange you need. It includes details like:

- Flanges you need

- Material grade

- Project

requirements: Specification, pipe size, connection type, facing, pressure class

Common flange specifications and standards

Custom forgings and special flanges and fittings can be designed to

meet any number of unique standards and specifications. Some common

classifications for custom pipe flanges include:

- Metric system

flanges

- Large industry

standard

- Tube turns

- CL 123 Lightweight

- ANSI

- ASME, and

- AWWA

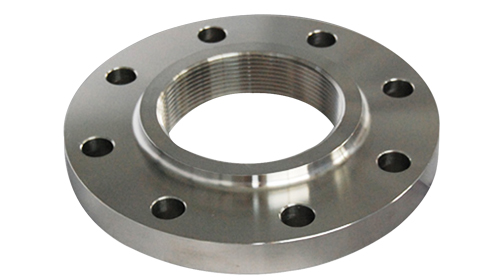

Custom flange types

Regardless of the custom specifications or size, the fundamental

design of most flanges falls under 6 common styles created to support, cover,

connect or close pipes and pipe systems.

The flange types include:

- Socket-weld flanges

- Threaded flanges

- Lap joint flanges

- Blind flanges

- Weld neck flanges

- Slip-on flanges

Performance and material grades

Custom pipe flanges need to manufacture from a wide variety of

material grades and materials. Carbon steel is one of the popular solutions, as

are specialty alloys and stainless steel, depending on the industry. Forged and

plate are also common, as are aluminum and titanium for lightweight jobs.

.png)

Comments

Post a Comment