Why Do Forging Flanges Need Heat Treatment?

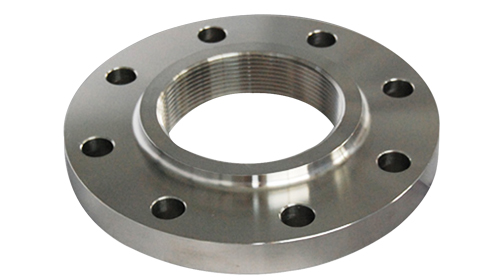

If you want to know why do forging flanges need heat treatment, you must first get an understanding of the meaning behind forgings. Forging is the use of a hand hammer, pressure equipment, or forging hammer on the mold on the heating of the metal blank force so that metal materials under the condition of non-separation plastic deformation obtain performance, size, and properties meet the requirements of parts. Need of heat treatment for the forged flange The main purpose is to refine the coarse grains, eliminate the residual stress and work hardening, reduce the hardness, improve the cutting performance, prevent the white spots while forging, and make sure about the required machinery and metal structure. Now, below are details about the heat treatment: Normalizing If you want to forge flange connections , heat treatment is the first step. Heat the forgings above the transformation temperature, form a single austenite structure, after a period of uniform temperature stability, after a