5 Common Valve Types Every Oil and Gas Engineer Should Know About

A valve is a mechanical device in a piping system used to control the flow and pressure of contents – liquid, oil, vapors, or gas. Here is a list of 5 standard valves that every oil and gas engineer should know:

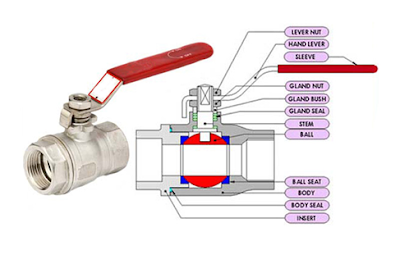

#1. Ball valves

It's a rotary motion quarter-turn valve.

It uses a ball-shaped disk to control the flow of components flowing in the

piping system. When you open the valve, the ball's holes come in line with the

body inlet, allowing contents to pass. The ball valves can withstand a

temperature between - 200 deg C and as high as 500 deg C. the best thing about

this valve is that it’s a quick-acting type.

Some of the different types of ball

valves include:

·

Floating

·

Trunnion Mounted

·

3 Way

·

Top entry

·

Side entry or split body

·

Three-piece body

#2. ARV or ARC valves

'Automatic Recirculation Valve' and 'Automatic Recirculation Control', are multifunctional valves. These valves' primary function is to ensure a pre-determined minimum flow keeps streaming through the centrifugal pump at all times. It’s necessary to maintain minimum flow as the centrifugal pump’s valves can get dry due to overheating, resulting in permanent damage to the valves.

#3. Butterfly valves

The butterfly valves are used to

stop, start and regulate flow. Th Quarter-turn rotary motion valve operates at

right angles to the flow. These short circular body valves are reliable, and their size may vary from 40 mm to 100 mm

and beyond. The simple construction of the valves facilitates easy pipe

arrangement. The various of using the butterfly valves include:

·

Simple and reliable

·

Quick-acting

·

Compact and light

·

Good regulating characteristics

· Low-pressure isolation

#4. Gate valves

This linear

motion valve is the most common type of valve. Gate valves are primarily designed to fit in a piping system that

requires minimum flow restriction. These valves are either kept fully open or

fully closed. When the valve is turned open, the gate disc allows the contents

to pass through the pipes. These valves don’t open or close quickly.

The various

types of gates valves available in the market are:

·

Split wedge or Parallel disks

Gate Valve

·

Non-rising Stem Gate Valve or

Insider Screw Valve

·

Flexible Wedge Gate Valve

·

Solid Wedge Gate Valve

·

OS & Y Gate Valve or Rising

Stem Valve

#5. Check Valve

These are

also known as non-return valves. The check valves prevent the back-flow of components

in the pipes by continuously keeping fluid moving in one direction. The check

valve is designed in a way that the pressure of the fluid

passing through a pipeline opens the valve, whereas any reversal of flow will

close the valve.

Different types

of check valves available in the market are:

·

Swing Type

·

Lift Type

·

Dual Plate Type

· Stop Check Valve

If you want to know more about these valves, do let us know in the comment section!

.png)

Comments

Post a Comment